Yucai Industry Area, Sanxin Town Zhangjiagang City, Suzhou, Jiangsu, China +8618205059569 [email protected]

The machine is designed for filling and sealing carbonated drinks, craft beer, and other beverages in PET bottles, PLA bottles, and glass bottles in the beverage industry. The filling and sealing processes are integrated into one design, and the principle of equal pressure filling is used.

Glass bottle can also be used. It just needs to change the conveyor parts.

Different models can satisfy various requirements of output from 1000B/H to 20000B/H.

The whole process is automatic, suitable for PET bottle, plastic bottle soda water and CSD beverage drinks.

Filling way using the gravity or micro pressure filling, make the speed faster and more stable, so compared with the same model our machine output is higher and more efficient.

The machine adopts advanced Mitsubishi programmable controller(PLC) to control the machine adopts advanced automatically, interworking with inverter running more stable and reliable the photoelectric sensor detect all part running state with high degree of automation, exasperation.

During the filling process, the empty bottle is guided into the bottle lifting cylinder through the pneumatic triplex parts. The bottle is then lifted, and the conical seal gasket under the filling valve seals the bottle. The filling valve's position turning block turns and opens the valve with the help of another cylinder. Air is injected into the bottle to create equal pressure. The beverage flows from a large material barrel through small conduits and fills the bottle. Once the liquid level in the bottle reaches the gas return pipe mouth, the filling process stops. The de-foaming valve slowly releases the air and pressure under the action of an arm. The bottle is then lowered by the can supporting cylinder. After the filling is complete, the bottle is sent to the sealing machine for sealing using a hook chain that runs in sync.

During the sealing process, the sealing wheel performs pre-sealing and then final sealing. Once sealed, the bottle is pushed out by the cap beating mechanism and transferred to the conveyor belt through a dial for further transportation.

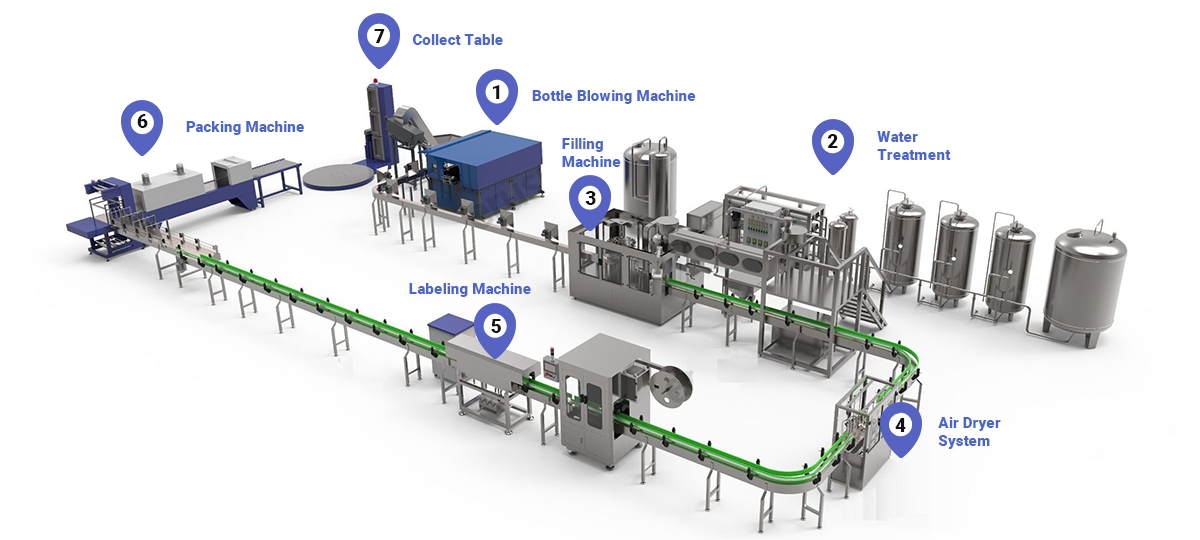

Water treatment system - RO system

Raw water tank→Water pump→Silica sand filter→Active carbon filter→Sodium ion exchanger → Precision filter→ Reverse Osmosis→UV-Sterilizer→Ozone Sterilizer →Finished Water tank

Carbonated mixing processing:

Mixing→ Sugar melting→ CO2 mixer→Buffering→Storage

Filling and Packing Line

Washing, Filling, Capping → Conveyor →Light checker→ Labeling machine→Code sprayer→PE film packing machine→Stock

Bottle Making Machine

PET preforms → Bottle blow molding machine → Finished Bottles

1) The overall appearance is comfortable, and the window-type structure can be used to keep an eye on the movement of the machine. If there is a problem, the machine can be stopped and checked in time.

2) PLC controller, simple and easy to operate, designed for foreign friends, allowing customers to easily navigate.

3) The whole machine material is made of stainless steel 304/316, which is very strong and guarantees the quality.

4) High filling accuracy and small error, ensuring efficiency while ensuring efficiency.

5)Three-in-one filling, the finished product, is short.

6) Fully automatic production, freeing hands, reducing labor required for production, saving costs and improving efficiency.

|

Model |

DCGF12-12-6 |

DCGF18-18-6 |

DCGF24-24-8 |

DCGF32-32-10 |

DCGF40-40-12 |

DCGF50-50-15 |

DCGF60-60-15 |

|

Production capacity |

2000-3000 |

3000-5000 |

5000-7000 |

7000-10000 |

10000-15000 |

16000-20000 |

20000-24000 |

|

Filling precision |

≤+5mm(Liquid level) |

||||||

|

Filling pressure (MPA) |

≤0.4 |

||||||

|

PET bottle specification(mm) |

(bottle diameter):Ф50-Ф115 ; (height):160-320 |

||||||

|

Suitable cap shape |

Plastic screw cap or crown cap |

||||||

|

Total power(KW) |

4.4 |

5.2 |

6.2 |

6.2 |

7.5 |

11 |

15 |

|

Weight (kg) |

2500 |

3500 |

4500 |

6000 |

7200 |

10000 |

15000 |

|

Overall dimensions(mm) |

2250x1650x2250 |

2600x1965x2250 |

2980x2200x2250 |

3880x2200x2250 |

4000x2250X2500 |

5500x3500X2500 |

6500x5500x2550 |

Main parts

|

S.N. |

Name |

Remark |

|

1 |

Washing head with bottleneck hanging |

Made by our factory |

|

2 |

Filling valve |

Made by our factory |

|

3 |

Sealing head |

Made by our factory |

|

4 |

Touch screen |

Siemens |

|

5 |

Transducer |

Delixi |

|

6 |

PLC |

Siemens |

|

7 |

Approach switch |

Atonics |

|

8 |

Light fiber switc |

Atonics |

|

9 |

Pneumatic elements |

Airtac |